Since the Industrial Revolution, the world of manufacturing has come a long way. Many innovations have shaped the way parts are currently made. Today, two manufacturing methods stand out – 3D printing and CNC machining.

These two processes have dominated the manufacturing landscape, and each offers unique advantages when making custom and precise parts. Though both methods shine in their own right, they are suited for different kinds of projects.

Understanding how each process works will help you choose the one that’s the best fit for your needs. This article will compare 3D printing and CNC machining, exploring how they differ and how you can make the most of each one.

Manufacturing Process

3D printing, a form of additive manufacturing, works just like it sounds – adding materials layer by layer to build up an object. Starting from nothing but a printing bed, the printer gradually builds the object by stacking materials. This makes it perfect for intricate designs that traditional methods would find tricky. Due to the process, 3D printing is often used for prototyping and even in the medical field for making prosthetics and implants.

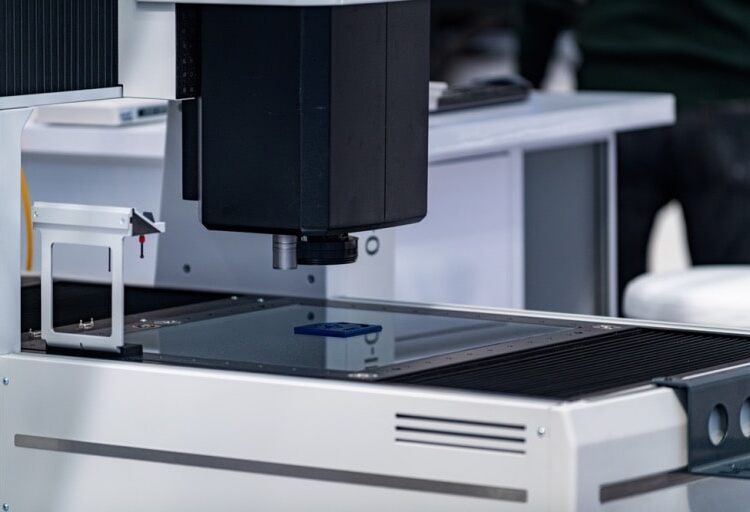

CNC machining or computer numerical control, on the other hand, takes the opposite approach. It uses a subtractive manufacturing method to remove material from a block of material to get the desired shape required. CNC machining is known for precision and smooth finishes, making it a go-to for projects like woodworking and engraving.

Materials and Strength

With 3D printing, you can use a broad variety of materials to work. Plastics, metals, and even ceramics are all materials compatible with 3D printing. However, most 3D-printed parts (especially those made from plastic) don’t have the same structural strength as CNC-machined parts.

Although high-end 3D printers can use stronger metals, CNC machining generally wins when it comes to durability. CNC machining supports a wider range of tough materials. These materials include metals like aluminum, steel, and titanium. So, when you need something strong, heat-resistant, and long-lasting, CNC machining should be your first choice.

Cost and Speed

3D printing tends to be less expensive when it comes to setup costs. This makes it ideal for prototypes or small production runs. Depending on the complexity of the design, it can be faster than CNC machining, especially for simple designs. However, you should note that large-scale 3D printing can take a lot of time. It invariably becomes more expensive as you print each part individually.

CNC machining, on the contrary, has higher setup costs because it requires specific tools and programming. However, once it’s ready to go, it churns out high volumes with consistent quality, making it a more cost-effective choice for mass production.

Precision and Tolerances

When it comes to precision and tolerance, CNC machining is the standard. It’s known for its micrometer-level accuracy. It is the top choice for industries where every little detail matters.

While 3D printing has improved a lot in precision, most consumer-grade printers still cannot quite match CNC’s razor-sharp accuracy. Industrial 3D printers are closing the gap. However, for jobs requiring intricate details, CNC machining is still the go-to.

Amount of Waste Generated

3D printing takes the eco-friendly route by using only the amount of material needed for the part. This effectively minimizes waste. However, the environmental impact of using certain raw materials like plastics can be a drawback.

CNC machining, on the other hand, produces more waste since it carves away material from a larger piece. Nevertheless, many manufacturers recycle excess material, reducing the impact on the environment.