From the noisy symphony of hand-cranked lathes to the smooth accuracy of today’s most advanced metalworking technology, the past of metal CNC machines is very exciting. Consider a time when machinists made each part by hand, using their knowledge and gut feelings to guide them.

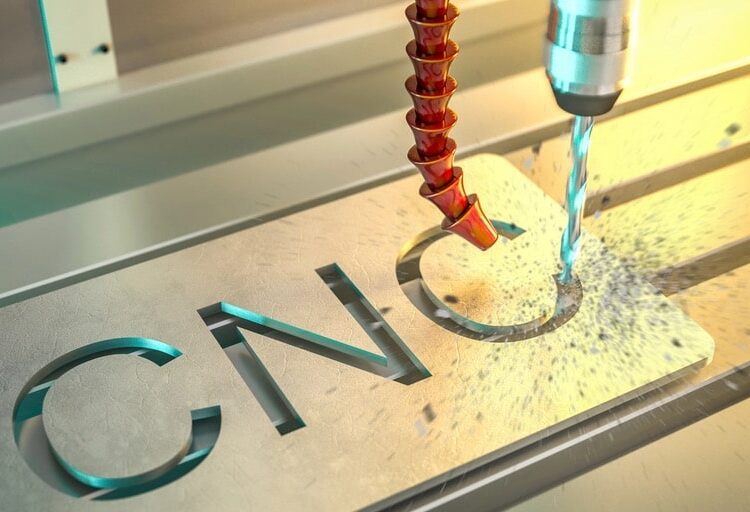

There is a change happening in technology right now, and automatic processes are taking over. This is altering the way we design and build metal fixtures.

For more artistic and open-minded people, metal CNC tools have made making things more accurate and faster. Although this change didn’t happen all at once, it happened in steps and over many years.

The Early Years: Manual Metal Machining

The first people to work with metal by hand used simple tools like chisels and saws around 700 BC. In a strange twist, working with metal by hand didn’t become more common until the Industrial Revolution in the 18th century.

Back in the day, trained workers made precise parts with lathes, mills, and tools that they turned by hand. After a long time and a lot of hard work, this process was finally done. In addition, it set the stage for future improvements in the speed and accuracy of cutting metal.

The Emergence of CNC Technology

These were the first computers that used numerical control (CNC). In the history of cutting metal, this was a big step forward. Punch cards and tape readers were used to automate the cutting process faster and more accurately on these early CNC machines.

We now use fully automatic CNC machines, but these machines were a step toward that. They were still run by hand, though.

The Rise of CNC Automation

Microprocessors and computer-aided design (CAD) tools changed the metal-cutting business a lot in the 1970s. Now engineers could write computer programs that could move machines with a level of accuracy that had never been seen before.

Stepper motors and better sensors have made it possible for metal CNC machines to be more accurate and work faster. Today, these tools are very important to business.

Recent Advancements: Multi-Axis and 3D Printing

In the past few years, metal CNC tools have changed and gotten better by adding 3D printing and cutting on more than one axis. To cut better and in more complex ways, they can move in more than one direction at the same time. 3D printing that builds on top of itself makes it easy to make complicated forms.

It has also changed how metal is made on a machine. These changes have made it possible to do new things in fields like health, engineering, and cars, where precision and complexity are very important.

Despite these advances, the true potential of metal CNC machining efficiency is only beginning to be realized. As industries continue to innovate, it’s essential to consider American manufacturing solutions to stay competitive and drive further progress in the field.

The Future of Metal CNC Machine: Endless Possibilities

When metal CNC machines went from being operated by hand to automatically, it completely changed the way things were done. Through its different steps of growth, this technology has pushed the limits of what is possible in manufacturing.

It has done this by making processes more efficient and accurate and by creating a huge range of new ideas. As we look to the future, it’s clear that the metal CNC machine will continue to change, leading to progress in many fields.

Does this article help you? Explore our website to find more helpful and fun stories that could help you.